Kitchen Sink v.1.0 Run-time libraries to support the Kitchen Sink, an all-purpose chemical process control board, based on the Atmel AVR ATmega1280 chip, using the Arduino core libraries.Recito v.5.0 Recito is a graphical modeling and process simulation.ODEMx is its successor, greatly enhanced to make real use of C++ features and with improved support for. ODEMx v.2.2 ODEM is a C++ class library for process simulation.Process Simulation Source Code Solution E-XD++ Diagrammer Enterprise v.15.01 UCanCode Releases Upgraded E-XD++ Visualization Suite V13.02.

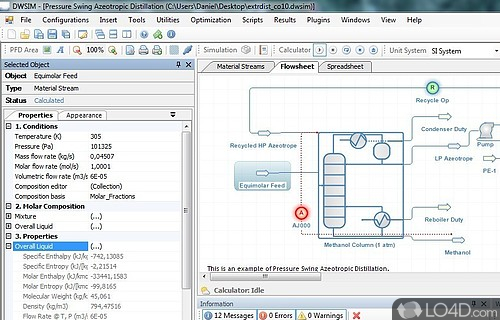

NET, DWSIM features a comprehensive set of unit operations, advanced thermodynamic models, support for reacting systems.

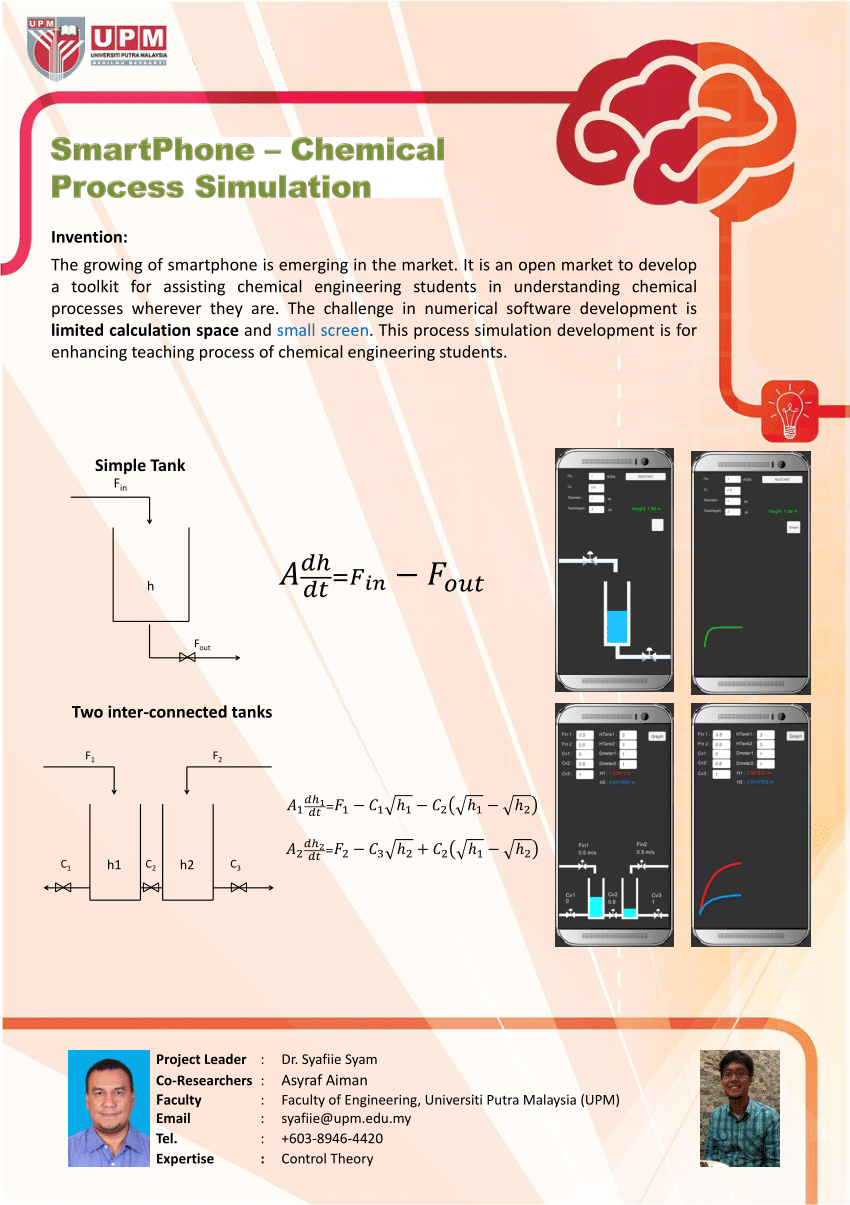

Knowledge of mass and energy balance concepts, solution techniques of differential equations, fluid mechanics, mass transfer and separation processes, thermodynamics, chemical kinetics and reaction engineering. Students will develop the ability to model some of the afore-mentioned processes from first principles using Matlab® and all other processes using commercial software packages, such as Aspen Plus and UniSim Design (accessible at Virtual Computing Lab at NCSU through Remote Desktop connection). Processes to model on both continuous and batch modes include heating/cooling, heat exchange, fluid flow, phase equilibria, flash operations, distillation, absorption/desorption, extraction, chemical reactions, and fermentation. The course will cover the use of some software packages to model chemical and biochemical processes and unit operations in stand-alone and combination modes.

0 kommentar(er)

0 kommentar(er)